Progress report - ESR 2: Afrina Khan Piya

date: May 02, 2022

category: News

Green-lubricated contacts through in-situ tribofilm formation using environmentally adapted nanotechnologies

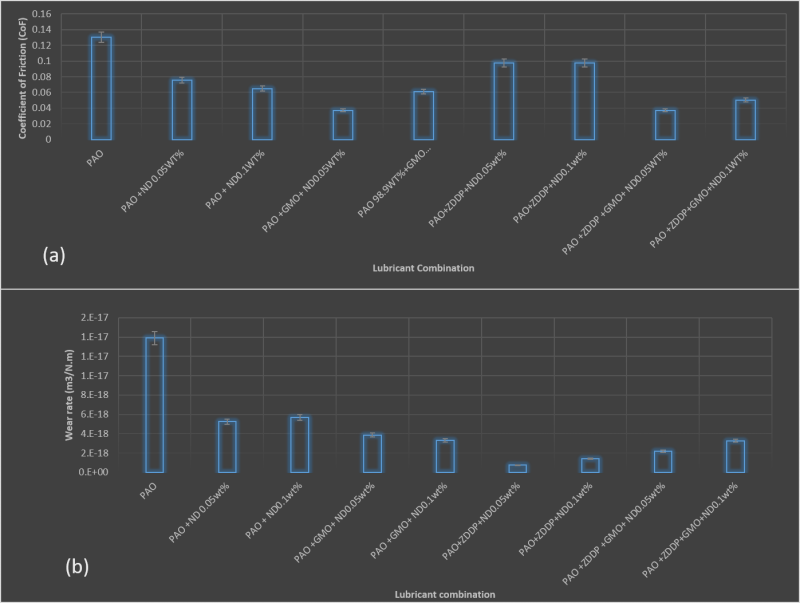

Because of the increasing concern for environmental safeguard, biodegradable and environment-friendly friction modifier has been explored especially for environment-sensitive industries. Researchers have shown promising results in friction reduction in DLC films by using organic friction modifier (glycerol monooleate – GMO), an anti-wear additive (zinc dialkyldithiophosphate – ZDDP) and its combination. Nanoparticles induced lubrication is an alternative technology used to enhance the friction and wear performance of engine parts. Detonated Nano Diamond (DND) has been considered as an effective additive. As they have better hardness, reduces real contact area that is considered one of the reasons for improved frictional properties. But incorporation of nanodiamonds(ND) with the lubricant combination with GM, ZDDP was not investigated yet. This work investigates the effect of diamond nanoparticles with synthetic oil PAO, organic friction modifier GMO and anti-wear additive ZDDP on tribological properties. Here, tribological performance of lubricant combination of PAO, GMO, ZDDP with 0.05wt% 0.1wt% ND and without ND was explored by using pin on plate tribometer in reciprocating motion at 80◦C. Synergistic effect was shown because of addition of ND with lubricant combination. The presence of ZDDP with ND alone in the formulation led to similar trend of friction as PAO base oil but significant reduction in wear. The addition of friction modifier GMO in ZDDP-based formulation without ND reduced the friction in the boundary lubrication regime to some extent. When ND was added to the combination friction and wear reduced significantly.